Bengal’s Dhaniakhali saree and dhoti are going global

Bengal has always been famous for its textiles and even the British frequently exploited the handloom weavers of this land to make them weave the best of Muslins and cotton handloom ware and take them back to Europe. British textile traders made huge profits in the process, leaving the weavers of Bengal a pauper, hardly paying them their dues. One of the regions that played a very important role in this textile boom was Dhaniakhali, a part of Hooghly-Damodar Plain and today lies in the Chinsurah subdivision.

The weave

The weave

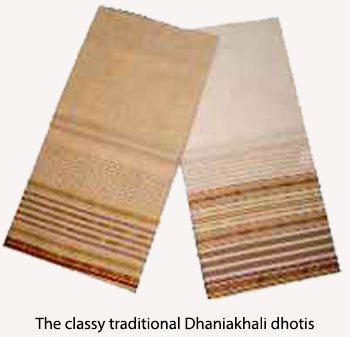

Dhaniakhali Saree has GI tag and traditionally has been in Kora or natural grey with either red or black plain border. The dyed yarn was first introduced in 1942. Dhaniakhali sarees nowadays are produced in Haripal, Rajbalhat Rasidpur, Dwarhata, Ramnagar, Gurap and Antpur of Hooghly. Normally, cotton yarns of 80s to 100s count are used both in warp and weft with extra warp of 2/100s or 2/80s cotton yarn.

One of its kind

One of its kind

Over the years the state government has been marketing the handloom sarees of Bengal, particularly the Dhaniakhali taant saree that even our Honourable Chief Minister Mamata Banerjee generally wears and has become a popular ‘brand ambassador’ of the same thus taking this saree to the global forum. The Bengal cotton sari has now turned into a fashion statement, wherever it is worn and have a market all over the world. Along with Dhaniakhali, Shantipur and Phulia taant are also marketed, but the Dhaniakhali sarees have a special place in everyone’s hearts.

The pure cotton woven sarees

The pure cotton woven sarees

In Dhaniakhali block every household has at least one loom. The sari produced here is thus named after the area. The material for the Dhaniakhali saree is somewhat coarse and heavier than other textiles from Bengal but suits the middle-class budget and as such is popular. Best part is it is very climate friendly and withstands the heat and humidity of India, keeping you comfortable. An ordinary Dhaniakhali saree takes a minimum of two days, pitching in 10–12 hours each day, to be woven. While the exotic ones take 4-5 days to weave and are sold for hefty sums. Interestingly, the Jamdani saris that originated in Dhaka and famous among the rich and aristocrats of the world are also produced in Dhaniakhali.

The weavers have co-operatives and many of them directly sell to the government and their stores which help the weavers get their dues on time. Tourists can take a day trip from Kolkata to tour the weaver’s village where the legendary Dhaniakal Tant Saree is woven and can visit weavers in their homes and watch them in action on their handlooms. The Dhaniakhali saree making process is unique. The Jaquard weaving technique is followed by weavers of Dhaniakhali. The different steps of the weaving process like shedding, picking, beating-up, left off and take up can be seen. It is fascinating indeed to watch the variety of designs of these sarees ranging from the simple elegant horizontal stripes to intricate fish and conch shell motifs. The vertically running woven braided line near the anchal or pallu, is the identifying factor for a Dhaniakhali Saree. Women testify that, after a few washes, the comfort of a Dhaniakhali Saree is unmatched! In the last few years, there has been a remarkable turnaround in the designs and the Dhaniakhali Saree is in vogue again. Students from leading design schools of the country like NIFT and NID are working on the latest designs for Dhaniakhali Sarees.

The weavers have co-operatives and many of them directly sell to the government and their stores which help the weavers get their dues on time. Tourists can take a day trip from Kolkata to tour the weaver’s village where the legendary Dhaniakal Tant Saree is woven and can visit weavers in their homes and watch them in action on their handlooms. The Dhaniakhali saree making process is unique. The Jaquard weaving technique is followed by weavers of Dhaniakhali. The different steps of the weaving process like shedding, picking, beating-up, left off and take up can be seen. It is fascinating indeed to watch the variety of designs of these sarees ranging from the simple elegant horizontal stripes to intricate fish and conch shell motifs. The vertically running woven braided line near the anchal or pallu, is the identifying factor for a Dhaniakhali Saree. Women testify that, after a few washes, the comfort of a Dhaniakhali Saree is unmatched! In the last few years, there has been a remarkable turnaround in the designs and the Dhaniakhali Saree is in vogue again. Students from leading design schools of the country like NIFT and NID are working on the latest designs for Dhaniakhali Sarees.

How to reach:

Around 2 hours drive from Kolkata. Best suited for a day trip.

Places to see around:

Several historical spots of Chinsurah and you can drop in at Tarakeshwar for a spiritual journey.